A groundbreaking development in plastic recycling has emerged from a German research team, offering a promising solution to one of the most pressing environmental issues of our time: plastic pollution. The team has pioneered an iron-catalyzed, solar-powered process capable of efficiently breaking down polystyrene plastic into valuable chemicals and producing clean hydrogen as a byproduct. This method presents a significant leap forward in both tackling plastic waste and generating sustainable energy, marking a major step in the transition to a circular economy.

The Problem: Plastic Pollution and Recycling Challenges

Plastic pollution continues to wreak havoc on the environment, with millions of tons of plastic waste accumulating in landfills, oceans, and natural ecosystems each year. Among the various types of plastic, polystyrene stands out as particularly problematic. Commonly found in packaging, disposable cutlery, and insulation materials, polystyrene is notoriously difficult to recycle through conventional methods. This presents a major challenge in efforts to reduce plastic waste and its harmful effects on the planet.

While recycling technologies have improved over the years, polystyrene remains a persistent issue due to its complex chemical structure and the fact that it is often contaminated by food or other substances. Most traditional recycling processes struggle to handle this type of plastic, leaving it to accumulate in waste streams and contributing to pollution.

The Solution: Iron-Catalyzed, Solar-Powered Recycling

The innovative solution proposed by the German research team revolves around an electrochemical process that uses an iron-based catalyst to break down polystyrene plastic. This method utilizes solar energy to power the reaction, creating an environmentally friendly process that leverages renewable energy.

In the process, the polystyrene is decomposed into smaller, valuable chemicals, including benzoic acid and benzaldehyde. These chemicals are important raw materials for various industrial applications, such as pharmaceuticals, fragrances, and even food additives. This opens up the possibility of using waste plastic as a resource for manufacturing goods, instead of it contributing to environmental degradation.

Additionally, the reaction produces hydrogen gas as a byproduct. Hydrogen is a clean and renewable energy source, often seen as a potential solution for reducing carbon emissions in industries like transportation and energy production. The fact that this recycling process generates hydrogen offers a dual benefit: it not only helps reduce plastic waste but also contributes to clean energy production.

The Benefits: Tackling Plastic Waste, Producing Clean Energy

This new recycling method offers a range of benefits that could help address two critical global challenges: plastic pollution and the need for sustainable energy sources.

- Reduced Plastic Waste: The ability to break down polystyrene into valuable chemicals reduces the amount of plastic waste that ends up in landfills and oceans. This process could significantly decrease the environmental footprint of plastics and reduce their harmful impact on marine and terrestrial ecosystems.

- Clean Energy Production: The generation of hydrogen as a byproduct provides an opportunity to create clean energy. Hydrogen fuel is considered a promising alternative to fossil fuels, as it produces no carbon emissions when used. This aligns with global efforts to transition to more sustainable, low-carbon energy systems.

- Circular Economy: By converting waste plastic into useful raw materials and clean energy, this technology supports the principles of a circular economy. In such a system, materials are kept in use for as long as possible, minimizing waste and maximizing the reuse of resources. Instead of being discarded, plastic waste can become a valuable input for other industrial processes, promoting sustainability and reducing reliance on virgin materials.

- Industrial Applications: The chemicals produced by the recycling process—benzoic acid and benzaldehyde—have a wide range of industrial uses. For example, benzoic acid is used in the production of preservatives and dyes, while benzaldehyde is a key ingredient in fragrances and flavorings. This creates an economic incentive to recycle plastic, as these valuable products can be sold or utilized in various sectors.

A Promising Step Forward

This breakthrough marks a significant step forward in the ongoing battle against plastic pollution and the quest for sustainable energy solutions. It showcases the potential of advanced recycling technologies and renewable energy integration, highlighting how science and innovation can work together to address some of the planet’s most pressing challenges.

As the method continues to be refined and scaled, it could play a crucial role in reducing plastic waste globally while contributing to the clean energy transition. Furthermore, by promoting a circular economy, it helps foster sustainable production and consumption practices, ensuring that resources are used more efficiently and waste is minimized.

The development of this iron-catalyzed, solar-powered plastic recycling method is not only a technological achievement but also a testament to the power of innovation in creating solutions that benefit both the environment and society at large. It offers hope for a cleaner, more sustainable future, where plastic waste no longer remains a burden but becomes a valuable resource for a circular and green economy.

Conclusion

The new method developed by the German research team represents a breakthrough in the field of plastic recycling. By efficiently converting polystyrene waste into valuable chemicals and clean hydrogen, the process holds the potential to address the dual challenges of plastic pollution and clean energy production. This innovation is a powerful example of how sustainable technologies can contribute to a circular economy, reduce environmental harm, and create new opportunities for industrial applications. As the world continues to grapple with the consequences of plastic waste, solutions like this offer hope for a more sustainable and cleaner future.

Related Content

- Breakthrough Method Converts Plastic Waste into High-Value Electronics Materials

- Choking on Plastic: The Global Crisis and the Call for a Treaty

- Tackling Plastic Pollution: The EU’s New Directive on Single-Use Plastic Bottles and Attached Caps

- Coral as a Microplastic Sink: A New Solution to the Ocean Plastic Crisis

- Bay Area Scientists May Have Found a Cure for the World’s Plastic Problem

- Startup Replaces 6 Million Plastic Bags with Eco-Friendly Corn Waste Alternative

- 1pc 600ml/20oz BPA Free Eco Friendly Portable Bottle Large Capacity Plastic Cup

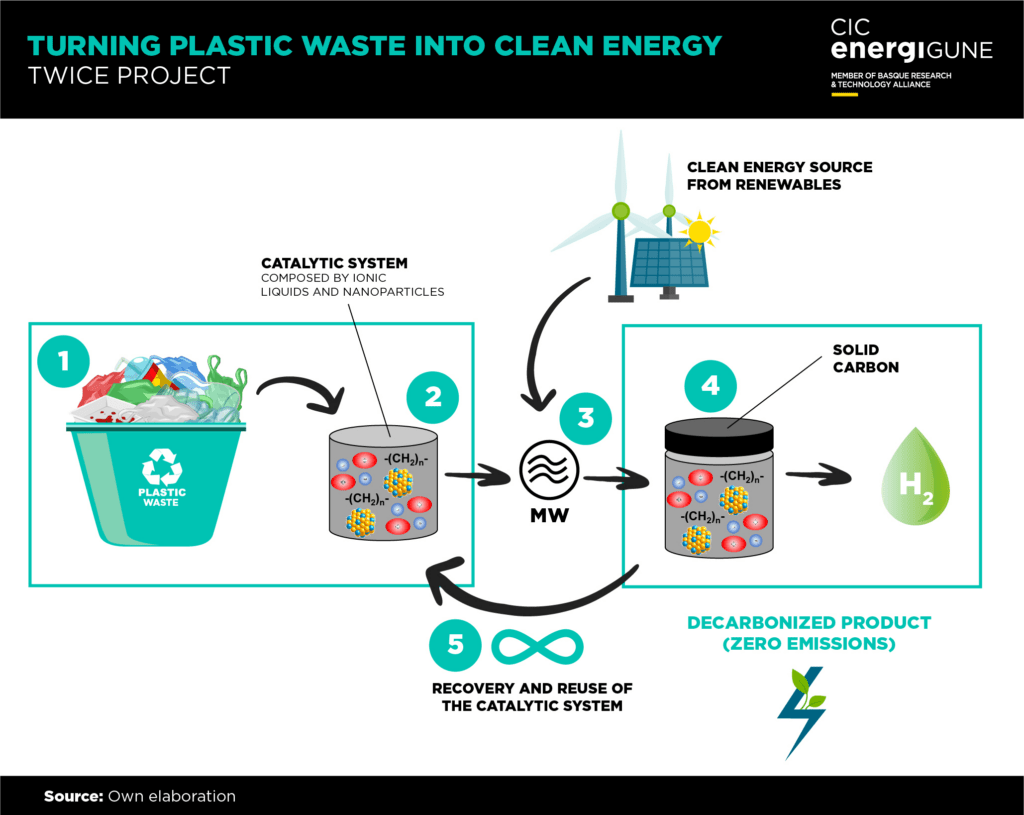

- Turning Plastic Waste into Clean Energy

- Chemical Recycling Technology Bringing Value to Plastic

- New method to convert plastic trash into clean hydrogen fuel