The Molecular Architects: Why the MOF Trio Deserved the Nobel

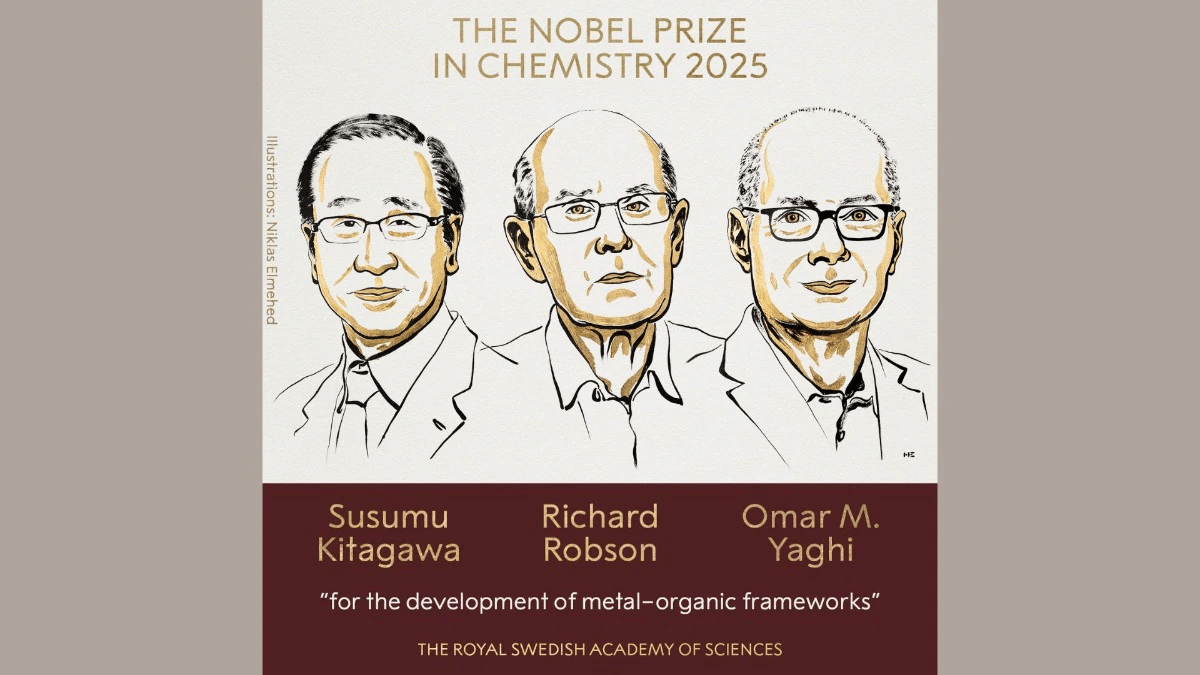

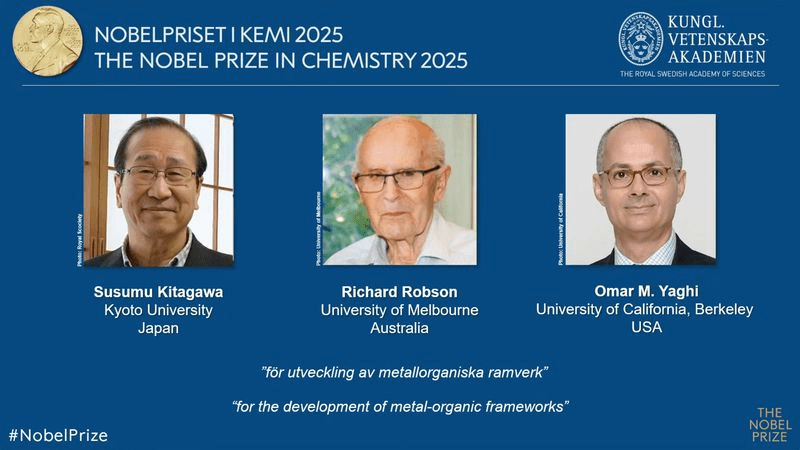

The 2025 Nobel Prize in Chemistry, awarded to Japan’s Susumu Kitagawa, UK-born Richard Robson, and American-Jordanian Omar M. Yaghi, isn’t just a nod to exceptional chemistry—it’s a dramatic acknowledgment of the technology most likely to help us engineer our way out of the world’s most pressing ecological crises. The material they pioneered, the Metal-Organic Framework (MOF), represents a quantum leap in material science, offering a previously unimaginable level of control over matter at the atomic level.

In simple terms, MOFs are molecular Lego sets. They are crystalline compounds formed by linking metal ions (the “nodes”) with rigid organic molecules (the “linkers”). The genius of the invention lies in the predictable, customizable assembly process that creates materials riddled with pores of perfectly uniform size, shape, and chemical function. This creates an internal surface area that is mind-bogglingly large. To grasp the scale: if you could unfold the inner surface area of just one gram of certain MOFs, it could cover an entire football field. .

Why is this important for the environment? Because our planet’s greatest challenges—capturing carbon, storing clean energy, and purifying water—are fundamentally problems of separation, storage, and catalysis. And that’s exactly what MOFs are custom-built to solve.

The Climate Change Anchor: Carbon Capture at the Molecular Level

The first and most direct environmental impact of the MOF revolution lies in the fight against atmospheric carbon dioxide (). For decades, industrial-scale carbon capture has been plagued by two major issues: inefficiency and high energy cost. Traditional methods, like amine scrubbing, require massive amounts of energy to heat the captured

and release it for storage.

Concrete Example: Direct Air Capture (DAC) and Flue Gas Scrubbing

MOFs fundamentally change the equation. The researchers learned to functionalize the internal surfaces of the MOF pores with specific chemical groups, turning them into highly selective molecular traps for .

Post-Combustion Capture: In coal or natural gas power plants, is mixed with nitrogen and water vapor in the flue gas. Conventional materials struggle to separate the

without excessive energy. MOFs can be designed to preferentially bond with

molecules, ignoring the rest. They function efficiently at lower temperatures and can release the captured

with far less energy input than liquid solvents, drastically cutting the operational cost and energy penalty of capture.

Direct Air Capture (DAC): The real game-changer is DAC, pulling directly from the ambient air, where its concentration is only about

parts per million (ppm). This is like trying to find a single grain of sand on a vast beach. MOFs, thanks to their massive surface area and highly specific capture chemistry, are currently among the most promising materials for DAC. Researchers have demonstrated MOFs that can operate using only low-grade heat, often achievable with solar power, turning the energy-intensive problem into a highly efficient, potentially decentralized system. The MOF acts as a passive sponge, soaking up the carbon until it’s saturated, then releasing a pure stream of

using minimal energy for sequestration or utilization (CCU).

This ability to pull out of smokestacks and, more importantly, out of the atmosphere, positions MOFs as a necessary anchor in achieving the net-zero emission goals set by global climate accords.

Addressing the Global Thirst: Water Harvesting from Desert Air

The second monumental ecological application of MOFs addresses the global water crisis. As the climate heats up, droughts intensify, and desertification expands, finding scalable and decentralized sources of freshwater becomes critical.

Concrete Example: Off-Grid Water Generation

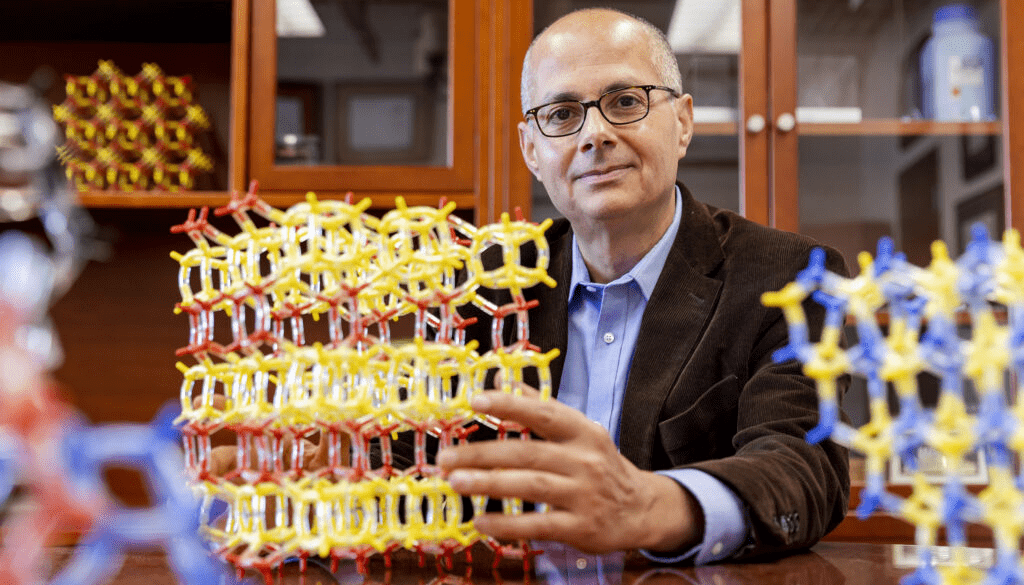

Professor Omar Yaghi’s work demonstrated a paradigm shift: certain MOFs, specifically tailored with highly hydrophilic (water-attracting) centers, can be designed to function as atmospheric water harvesters.

The Mechanism: These MOFs are capable of absorbing water vapor from air, even in arid conditions with relative humidity levels as low as . Crucially, they hold the water tightly enough to saturate the pores but release it readily when exposed to low-grade heat, such as that provided by ambient sunlight or solar thermal panels.

The Impact: This MOF-powered system can be packaged into small, off-grid devices that require no electricity and no traditional plumbing. Imagine a small box placed on a rooftop in a remote, water-stressed village. Using the energy of the sun, it draws moisture from the air overnight and releases potable water during the day. This technology bypasses the need for massive, centralized desalination plants (which are energy-intensive and produce harmful brine waste) or the transport of water over long distances. It promises a truly sustainable, personalized, and hyper-local water solution, directly combating water scarcity driven by climate change.

The Green Chemistry Revolution: Catalysis and Energy Storage

Beyond capture and purification, the MOF design architecture is rewriting the rules of industrial chemistry. This is the realm of green chemistry, which seeks to reduce or eliminate the use and generation of hazardous substances.

Concrete Example: Low-Energy Catalysts

A traditional catalyst, often made from expensive and rare platinum or palladium, works only on its surface. MOFs, however, can embed catalytic sites directly within their internal porous structure. This allows chemical reactions to take place hundreds or even thousands of times more efficiently because the MOF controls the exact chemical environment and channels the reactant molecules precisely to the active sites.

Methane Conversion: Methane () is a greenhouse gas far more potent than

. MOFs are being developed to catalyze the conversion of methane, often captured from landfills or oil infrastructure, into valuable, liquid chemical feedstocks like methanol. This conversion, which typically requires massive heat and pressure, can be achieved at far milder conditions using MOF catalysts, mitigating a potent GHG while creating a useful product—a true win-win for the economy and the environment.

Hydrogen Storage (Clean Energy Infrastructure): The transition to a clean energy economy relies heavily on hydrogen () as a zero-emission fuel source. A major challenge is storing it safely and efficiently. MOFs offer extremely high-density storage capacity due to their vast internal surface area. Hydrogen molecules can be adsorbed onto the MOF’s surface, packing much more gas into a smaller volume than high-pressure tanks alone. This breakthrough is essential for making hydrogen-powered vehicles and energy infrastructure practical and safe.

The Data Behind the Hype: Comparing MOF Capacity

To truly appreciate the MOF advantage, one must look at the numbers. The key metric is surface area, which determines how much gas or liquid can be stored or captured.

| Material Category | Role | Surface Area (m²/g) |

| Zeolites | Traditional Catalysts & Adsorbents | 500 to 800 |

| Activated Carbon | Industry Benchmark (e.g., Filtering) | 1,000 to 2,500 |

| High-Performance MOFs (e.g., MOF-177, NU-1000) | Next-Gen Adsorbents & Catalysts | 4,000 to over 10,000 |

The table demonstrates that MOFs can offer two to five times the surface area of the best traditional adsorbents. This exponential increase means a device using MOFs can be significantly smaller, lighter, and operate with far lower energy input to achieve the same ecological task, whether it is filtering air or storing fuel. This is the material breakthrough that makes large-scale climate solutions economically viable.

The Human Element: From Lab Bench to Living Room

The story of MOFs, like all great scientific breakthroughs, is also a human story of persistence. Kitagawa, Robson, and Yaghi spent years figuring out how to control the molecular geometry. The initial hurdles were formidable: ensuring the crystalline structure didn’t collapse when the solvents were removed (a process called “activation”) and proving that the highly porous material was stable enough to survive industrial conditions.

This journey from an obscure laboratory concept to a Nobel-winning technology embodies the relentless human curiosity that fuels progress. It’s a powerful reminder that the biggest solutions often start at the smallest scale—the atomic scale.

Solutions for the Future: Scaling the Molecular Playground

While the Nobel recognition solidifies MOFs’ scientific standing, several steps are needed to translate this molecular playground into global ecological salvation:

- Industrial Scaling and Cost Reduction: Current MOF production is often complex and expensive. We need breakthroughs in large-scale, continuous manufacturing processes to drive the cost down, making MOFs competitive with activated carbon and silica gels. Research must focus on using cheaper, more abundant metal nodes (like iron or aluminum) instead of expensive rare metals.

- Durability and Regeneration: For MOFs to be effective in industrial settings (like filtering smokestacks), they must withstand heat, pressure, and chemical contaminants. Future research must prioritize MOF designs with enhanced thermal and chemical stability, alongside low-energy, repeatable regeneration cycles for perpetual reuse.

- Integration into Existing Infrastructure: The next phase involves engineering MOFs into practical formats—pellets, coatings, or membranes—that can be seamlessly integrated into existing industrial infrastructure, from HVAC systems (for better air quality) to automotive fuel cells (for hydrogen storage).

- MOFs in Water Decontamination: Beyond atmospheric water harvesting, MOFs show immense promise for removing per- and polyfluoroalkyl substances (PFAS), heavy metals, and pharmaceutical residues from industrial wastewater—a critical emerging ecological threat.

Call to Action: Investing in the Invisible

The Nobel Prize highlights the power of fundamental chemistry to address existential threats. For policymakers, investors, and the public, the implications are clear:

- Fund Basic Material Science: We must increase investment in fundamental material science research, understanding that the greatest technological shifts—like MOFs—come from foundational discoveries, not incremental engineering.

- Incentivize Adoption: Governments and industry leaders must create tax incentives and regulatory frameworks that prioritize the adoption of MOF-based solutions in carbon capture, hydrogen storage, and water treatment over older, less efficient, and higher-emission technologies.

- Demand Green Products: As consumers, we can support companies (and pressure others) that explicitly invest in next-generation green manufacturing techniques, including those that use MOF-based catalysts to reduce energy and waste in their chemical processes.

The Metal-Organic Framework is more than just a chemical breakthrough; it is a molecular tool that gives humanity unprecedented control over the elemental forces driving climate change. Thanks to the Nobel-winning work of Kitagawa, Robson, and Yaghi, we now have custom-designed molecular sponges that can literally clean up the planet—one molecule at a time. The real work is just beginning.

Related Videos

Related Content

- Press release: Nobel Prize in Chemistry 2025 – NobelPrize.org

- Chemistry Nobel awarded to three scientists for their work on metal organic frameworks

- Nobel prize in chemistry awarded to scientists for work on ‘Hermione’s handbag’ | The Guardian

- Nobel Prize in Chemistry Awarded to Architects of Metal-Organic Frameworks – The New York Times

- Nobel chemistry prize 2025: metal-organic frameworks win for Kitagawa, Robson and Yaghi

- Nobel Prize in chemistry goes to scientist trio for Harry Potter-like work in molecular architecture

- French physicist Pierre Agostini, 2023 Nobel laureate in physics

- The Green Revolution Is Accelerating—And It’s Smarter Than Ever

- The Healing Sky: How Human Action and Global Cooperation Rescued the Ozone Layer in 2025 – A Blueprint for Earth’s Future

- Elon Musk and Mark Zuckerberg Lack Moral Values, Says Joseph Stiglitz: Apple as an Ethical Alternative Model

- The Impact of NGOs on Global Development: Success Stories and Challenges

- Guardians of Green: How NGOs Lead the Charge in Preserving Our Planet

- The Quantum Investment Frontier: Why D-Wave, Rigetti, and IonQ Are Not Just Tech Stocks, But Climate Assets

- Why Sustainability is Like a Bad First Date (But Ends Our True Love) 🙂

- Bio photovoltaic Systems: The Next Evolution in Solar Energy

- Stanford Scientists Unveil a Faster, Cheaper Method to Lock Away Carbon Permanently

- Organic Molecules in the Universe: Implications for the Origins of Life

- The Carbon Sink Crisis: Challenges and Solutions