Intro

Stanford University researchers have pioneered an innovative, low-energy technique to capture and store atmospheric carbon dioxide (CO2) using heat-treated minerals. By turbocharging a natural process called weathering, their method transforms common minerals into highly reactive materials that soak up CO2 at remarkable speeds. This breakthrough could seamlessly blend with industries like agriculture, offering a dual benefit: pulling carbon from the air while enriching soil and boosting crop health.

Stanford chemists have devised a cost-effective solution to permanently remove CO2 from the atmosphere, tackling the pressing challenge of global warming. Their process hinges on heating abundant minerals to create reactive compounds that lock away carbon in stable forms. Best of all, it leverages existing technology—like the kilns used in cement production—making it practical and scalable.

“The Earth is brimming with minerals that can naturally strip CO2 from the air, but they’re too slow to keep pace with human emissions,” said Matthew Kanan, a Stanford chemistry professor and senior author of the study, published in Nature. “Our method speeds things up in a way that’s affordable and ready to scale.”

In nature, silicate minerals react with water and CO2 over centuries, forming stable bicarbonates and carbonate solids—a process called weathering. Scientists have long sought to accelerate this, and Stanford’s team has cracked it. Kanan and postdoctoral scholar Yuxuan Chen developed a technique to transform sluggish silicates into fast-acting carbon absorbers. With support from Stanford’s Sustainability Accelerator, they’re now testing real-world applications.

“We came up with a simple ion-exchange reaction to wake up these dormant minerals,” said Chen, the study’s lead author, who perfected the method during her PhD. “The results blew us away—it works better than we ever imagined.”

With climate experts warning that we must both cut fossil fuel use and remove billions of tons of CO2 to halt warming, current carbon capture tech—like direct air capture—remains expensive and energy-hungry. Kanan’s approach? “It uses less than half the energy of top direct air capture systems and could compete on cost,” he said.

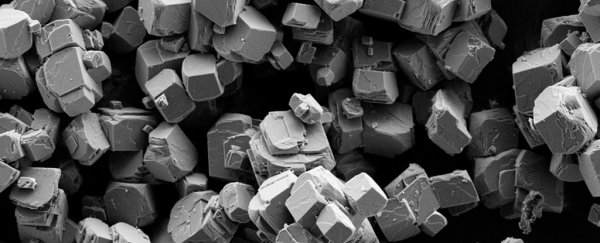

The team drew inspiration from cement-making. Limestone is heated to 1,400°C to produce calcium oxide, which is then mixed with sand. Stanford’s twist? They pair calcium oxide with magnesium-rich silicates in a kiln. The heat triggers an ion swap, yielding magnesium oxide and calcium silicate—two super-reactive minerals that gobble up CO2.

“It’s like a force multiplier,” Kanan explained. “You start with one reactive mineral and an inert one, and end up with two that are ready to trap carbon.” In lab tests, these minerals fully carbonated in two hours when exposed to pure CO2 and water. In ambient air (with far less CO2), it took weeks to months—still thousands of times faster than natural weathering.

The team sees big potential beyond the lab. “Picture spreading these minerals over vast areas to pull CO2 from the air,” Kanan said. One promising use? Agriculture. When added to soil, the minerals weather into bicarbonates that flow to the ocean for permanent storage—while also acting as a natural soil enhancer.

Farmers already use calcium carbonate to adjust soil pH. “Our material could replace that,” Kanan noted. “Plus, as calcium silicate breaks down, it releases plant-friendly silicon, potentially boosting yields and resilience. Farmers might even pay for it—not just for carbon removal, but for healthier crops and soil.”

Currently, Kanan’s lab produces 15 kilograms of material weekly. To dent global CO2 levels, though, millions of tons would be needed annually. The good news? The process can piggyback on cement kiln designs and tap abundant minerals like olivine and serpentine—common in places like California and even mining waste.

“Over 400 million tons of silicate-rich mine tailings are produced yearly,” Chen said. “And Earth holds over 100,000 gigatons of these minerals—enough to offset all human CO2 emissions, ever.”

Each ton of material could remove a ton of CO2, even after factoring in kiln emissions (if powered by gas or biofuel). For reference, 2024’s fossil fuel emissions topped 37 billion tons.

To ditch fossil fuels entirely, Kanan is teaming up with Stanford’s Jonathan Fan to design electric kilns. “Cement kilns already produce billions of tons and last decades,” Kanan said. “With that blueprint, we can go from lab to global impact.”

Key Challenges for the Future

While Stanford’s breakthrough is promising, scaling it to meaningfully curb climate change faces several hurdles. Heating minerals in kilns requires significant energy. Even with electric kilns, the carbon footprint depends on clean energy availability. If powered by fossil fuels, emissions could offset gains—commenter Clyde Spencer rightly flags this as needing a full lifecycle analysis.

Competing with direct air capture on cost sounds great, but production, transportation, and application (e.g., spreading minerals on fields) must remain affordable at scale. Without subsidies or farmer buy-in, adoption could stall. Dumping bicarbonates into oceans via soil runoff sounds clever, but as Spencer notes, the ecological consequences—like altering ocean chemistry—are underexplored. Could this spark unintended ripple effects?

Producing millions of tons annually requires massive industrial expansion. Repurposing cement kilns helps, but mining, processing, and distributing minerals like olivine globally is a logistical beast—especially if suitable deposits aren’t local. Some comments reflect skepticism about CO2 removal, fearing it harms plants or serves hidden agendas. Overcoming resistance and securing regulatory support will be critical for deployment.

This method’s success hinges on solving these practical and perceptual challenges—turning a lab win into a planet-scale fix won’t be simple, but it’s a bold step forward.

Related Content

- Scientists Discover Low-Cost Way to Trap Carbon

- ChatGPT’s Carbon Footprint: Study Reveals AI Produces CO2 Equivalent to 260 Flights from NYC to London Monthly

- Understanding Carbon: 10 Terms to Know and How You Can Take Action

- Revolutionizing Carbon Capture: UC Berkeley’s COF-999 Material Shows Promise in Combatting Climate Change

- Chonkus: A Carbon-Hungry Microbe Revolutionizing Carbon Capture

- Billionaires and Their Carbon Budgets: Unpacking Oxfam’s Alarming Report

- Reducing Sustainability and Waste Impacts Through Carbon Emissions by Countryi

- US researchers unveil low-cost, high-impact CO2 capture

- Scientists Unveil Cost-Effective Carbon Capture Method

- How heating rocks could help solve the climate crisis