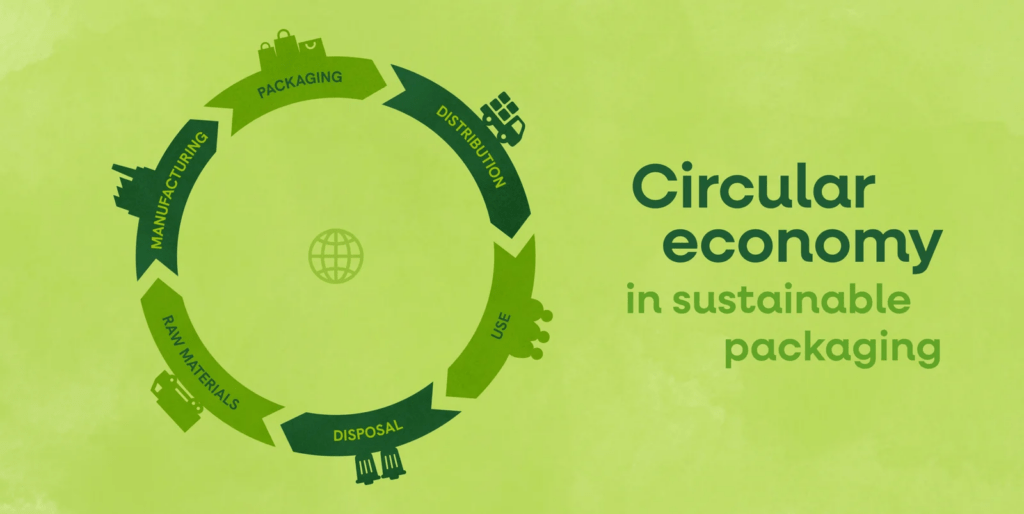

Jindal Films Europe (JFE) is making significant strides in the world of sustainable packaging, actively shaping the future of eco-friendly solutions in the flexible packaging sector. As a leader in the industry, JFE is deeply committed to developing innovative, sustainable packaging films that reduce environmental impact and foster a circular economy. The company’s focus on recyclable, biodegradable, and energy-efficient packaging solutions is helping to drive the packaging industry toward more sustainable practices, and it is becoming a key player in the global movement to minimize plastic waste.

This article explores JFE’s sustainable packaging innovations, how the company is integrating circular economy principles into its operations, and potential solutions for a more sustainable packaging future.

Key Innovations and Initiatives by JFE

JFE’s commitment to sustainability is clearly reflected in its continuous development of innovative products and technologies designed to minimize the environmental impact of packaging while meeting the growing demands of modern consumers for high-performance, functional, and eco-friendly solutions. Through consistent product launches and cutting-edge innovations, JFE is shaping the future of sustainable packaging.

Each year, JFE introduces between five to ten new sustainable film products, underscoring its proactive approach to addressing environmental challenges such as plastic waste and resource depletion. This commitment to innovation is not only in response to market demand but also part of JFE’s strategy to expand the availability of eco-friendly packaging solutions across diverse sectors, including food and beverage, personal care, and beyond. These new products include recyclable packaging materials and films designed with reduced carbon footprints, marking a significant step toward a more sustainable future.

Among its most notable innovations is JFE’s recyclable Biaxially Oriented Polypropylene (BOPP) films. Traditionally, BOPP films are favored for their durability, clarity, and resistance to heat, making them a staple in packaging applications. However, their environmental impact has been a concern due to their low recyclability. JFE’s development of fully recyclable BOPP films is a groundbreaking achievement, reducing the ecological footprint of this widely used material. By embracing the principles of the circular economy, these recyclable films promote the reuse of materials, cutting down the waste sent to landfills and contributing to a more sustainable packaging lifecycle.

Furthering its environmental mission, JFE has introduced metalized and Alox barrier films as sustainable alternatives to traditional aluminum foil. While aluminum foil has excellent barrier properties, it is notoriously difficult to recycle, contributing to environmental strain. JFE’s metalized and Alox films provide the same protective benefits, extending shelf life and maintaining product freshness, but can be seamlessly integrated into recycling systems. This innovation offers a greener alternative for brands that are looking to reduce the environmental impact of their packaging without sacrificing quality.

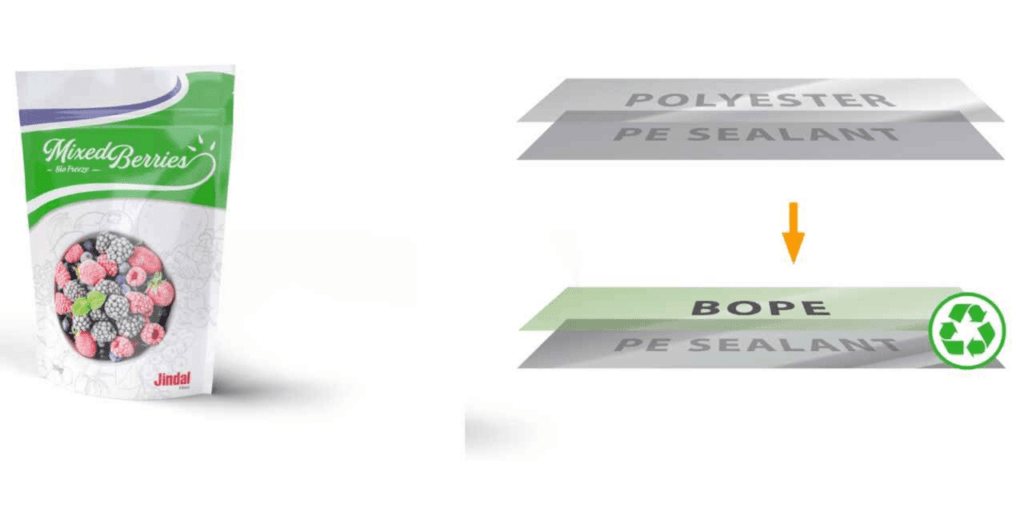

JFE’s Ethy-Lyte BOPE platform represents another leap forward in sustainable packaging technology. This platform enables the creation of mono-material, recyclable packaging structures, particularly for Biaxially Oriented Polyethylene (BOPE) films. The shift toward mono-material packaging simplifies the recycling process by eliminating the complexity associated with multi-material packaging, which often cannot be recycled efficiently. This innovation is key to advancing the circular economy, making it easier for brands to use recyclable materials and reduce waste.

JFE’s commitment to sustainability extends beyond product development to its manufacturing practices. The company uses energy-efficient production methods to minimize environmental impact while maintaining high-quality output. This focus on energy efficiency plays a pivotal role in reducing the overall carbon footprint of JFE’s packaging solutions. Additionally, JFE is dedicated to optimizing resource usage across its production chain, ensuring responsible raw material consumption and reducing waste at every stage of the process.

Recognizing that sustainability in packaging is a collective effort, JFE fosters collaborations with industry partners, suppliers, and customers to drive sustainable change. Through these partnerships, JFE leverages collective expertise to develop and implement innovative solutions. Collaborating with recyclers and waste management companies, JFE also works to improve packaging recycling infrastructure, promoting responsible end-of-life management and helping to close the loop on packaging waste.

In sum, JFE’s continuous innovation and dedication to sustainability position the company as a leader in eco-friendly packaging solutions, committed to reducing environmental impacts while meeting the evolving needs of global consumers.

Potential Solutions and Future Directions for Sustainable Packaging

While JFE has already made significant strides in advancing sustainable packaging, there are several additional solutions the company could pursue to further reduce its environmental impact and continue leading the industry toward a more sustainable future.

One area with promising potential for development is biodegradable films. While recyclable films are a step forward, biodegradable options can provide an even greater opportunity to reduce waste. These films would naturally break down after use, leaving no harmful residues behind. JFE could explore the development of biodegradable films made from renewable resources, such as plant-based polymers, which could be particularly useful in single-use applications like food packaging. This innovation could significantly cut down the environmental burden of waste, particularly in applications where fast decomposition is crucial.

In addition to biodegradable films, JFE could focus on minimizing plastic usage in its packaging products. Reducing the volume of plastic used can directly lower the environmental footprint of packaging. This could be achieved by incorporating thinner films, lightweight materials, or alternative substances that offer the same functionality as traditional plastics but with reduced ecological impact. Such efforts would also resonate with eco-conscious consumers who prefer minimalist packaging with less material waste.

Another key area for improvement is the recycling infrastructure necessary to support the growing demand for recyclable packaging. While JFE’s commitment to producing recyclable films is commendable, the success of these efforts is heavily reliant on efficient recycling systems. JFE could collaborate with governments, industry partners, and recyclers to enhance waste management and sorting technologies. This could involve innovating new collection systems for post-consumer packaging or improving the efficiency of sorting mixed-material packaging. Additionally, consumer education on proper recycling practices could help increase recycling rates, further optimizing the lifecycle of packaging materials.

Finally, raising consumer awareness about the importance of sustainable packaging and the benefits of eco-friendly products is an essential step forward. Despite the increasing demand for sustainable options, many consumers still lack the knowledge to make informed choices. JFE could leverage its brand presence to educate the public on the environmental impact of packaging waste. This could include campaigns that highlight the recyclability or biodegradability of packaging through clear labeling schemes, making it easier for consumers to select environmentally responsible products.

By focusing on these strategies, JFE can continue its leadership in sustainable packaging, driving further innovation and contributing to a more sustainable packaging ecosystem globally.

Conclusion: JFE’s Role in a Sustainable Packaging Future

JFE’s dedication to sustainable packaging is paving the way for the future of the industry. Through innovative product designs, sustainable manufacturing processes, and strategic partnerships, the company is helping to drive the packaging sector toward a more sustainable and circular future. The company’s focus on recyclable BOPP films, barrier films, and the Ethy-Lyte BOPE platform showcases how innovation can address key sustainability challenges and create practical solutions for businesses and consumers alike.

By exploring further innovations like biodegradable films, reducing plastic usage, and collaborating on recycling infrastructure, JFE can continue to lead the way in sustainable packaging. As the world increasingly shifts toward a circular economy, JFE’s contributions are helping to shape the packaging industry’s role in building a greener, more sustainable future.

Related Content

- Jindal Films Europe to launch 5-10 new sustainable packaging

- Huhtamaki’s OmniLock Ultra Paper: A Game Changer for Sustainable Packaging

- Branded Merchandise: Go Green for a Sustainable Future

- Green Bubble Gorgeous: Luxurious Self-Care Made Simple and Sustainable

- Marie Claire UK Sustainability Awards 2024: A Celebration of Sustainable Innovation

- Ultra-Luxurious Bamboo Comforters: Redefining Sustainable Luxury

- Comilla Cotton’s Eco-Friendly Renaissance: A Blueprint for Sustainable Agricultural Innovation

- Packaging design for the circular economy

- Circular Economy: Measuring innovation in the product chain

- Sustainable Packaging Innovations: Trends to Embrace in 2024